Sep 05, 2018 · mig if at 275 amps then yes penetration might be higher unless you are stick welding at 275 amps. obviously lincoln welding procedure handbook might recommend using 7/32 welding rod at 275 amps or more for welding 1/4 or thinner plate too. i never used bigger than 3/16 7018 rod it has a range of 180 to 300 amps. penetration aint that bad at

Sep 05, 2018 · mig if at 275 amps then yes penetration might be higher unless you are stick welding at 275 amps. obviously lincoln welding procedure handbook might recommend using 7/32 welding rod at 275 amps or more for welding 1/4 or thinner plate too. i never used bigger than 3/16 7018 rod it has a range of 180 to 300 amps. penetration aint that bad at

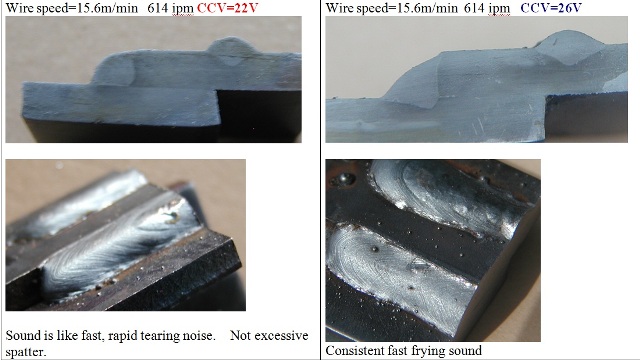

MIG Weld Penetration 02-07-2011, 02:35 PM. What constitutes good penetration using a MIG welder. I have two Millermatic welders. The older is a Millermatic 35 in which I run .035 wire, the newer is a Millermatic 185 in which I run .023 wire. Is the following an accurate definition of penetration ?

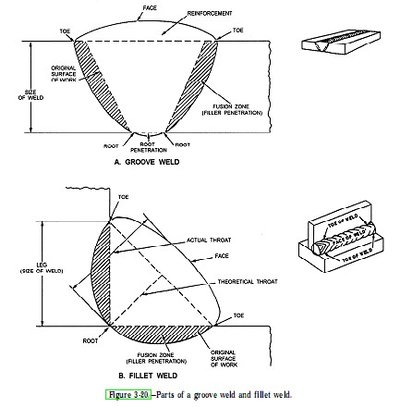

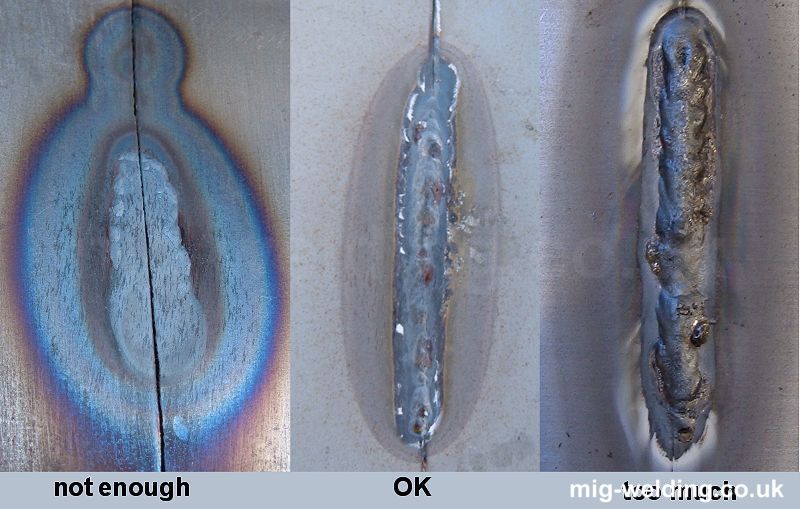

Common Weld Faults Incomplete Penetration. This term is used to describe the failure of the filler and base metal to fuse together at the root of the joint.

Want to learn about MIG welding techniques? Then this is the page for you to visit! Forehand welding produces shallow penetration with a flat wide smooth surface. The second is backhand method where you drag the MIG gun like a Stick welder. This produces a deep penetration weld that is narrow and is high in the center. In most cases you

MIG Welding Shielding Gas Basics. MIG (GMAW) welding with shielding gas and a solid wire electrode produces a clean, slag-free weld without the need to continually stop welding to replace the electrode, as in Stick welding.

Want to learn about MIG welding techniques? Then this is the page for you to visit! Forehand welding produces shallow penetration with a flat wide smooth surface. The second is backhand method where you drag the MIG gun like a Stick welder. This produces a deep penetration weld that is narrow and is high in the center. In most cases you

Welding Process: the various arc welding processes have associated weld penetration characteristics. For example, the SAW, FCAW and GMAW (in a globular, spray or pulse spray arc metal transfer mode) processes are known in general for higher levels of weld penetration.

100% penetration is necessary for full strength on butt weld joints, for fillet welds penetration into the root is important but 100% is not practical. for thick to thin butt welds, penetration and cross sectional thickness of at least the thinner member is usually the goal.

Sep 29, 2015 · see the full article here http://goo.gl/6lkkHK visit the store here http://weldmongerstore.com/ Mig welding settings have a definite effect on penetration. Wire speed